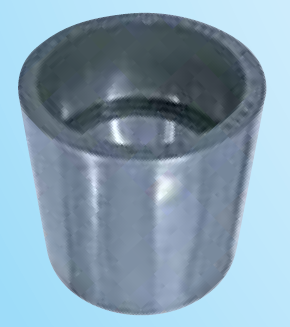

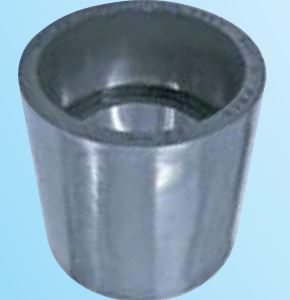

“Socket” in PVC plumbing refers to a type of end configuration on a PVC pipe or fitting. It is a smooth, plain opening without any threads, designed to receive the plain end of another PVC pipe or the plain end of a fitting. The socket provides a secure connection between two PVC components when used with PVC solvent cement or glue.

Here are some key points about the “socket” in PVC plumbing:

Socket End: The socket end of a PVC pipe or fitting does not have any external or internal threads. It is a smooth, unthreaded opening that allows for a slip-fit connection.

Solvent Cement: When joining PVC pipes or fittings with socket ends, PVC solvent cement is used to create a strong and leak-resistant bond. The solvent cement chemically fuses the PVC material together, effectively creating a continuous and watertight connection.

Slip-Fit Connection: A slip-fit connection is made by inserting the plain end of a PVC pipe or fitting into the socket of another PVC component. The solvent cement is then applied to the joint, and the pieces are pushed together until they are fully seated.

PVC Material: PVC (Polyvinyl Chloride) is the material from which both the socket end and PVC pipes/fittings are made. PVC is widely used in plumbing and construction due to its durability, cost-effectiveness, and resistance to corrosion and chemical damage.

The socket end is a crucial feature of PVC pipes and fittings, as it allows for straightforward and reliable connections in PVC plumbing systems. It is commonly used in water supply lines, drainage systems, irrigation systems, and various other applications where PVC pipes are used. Proper solvent welding techniques are essential to ensure a secure and leak-free joint when using socket connections in PVC plumbing.

Top of Form